MARS 6 Synthesis

MARS 6 Synthesis

Parallel & Scale-Up Microwave Synthesizer.

Parallel microwave synthesis for teaching and industrial laboratories

The MARS™ 6 Synthesis is a multi-mode microwave system that provides parallel reaction processing, under uniform conditions. The ability to run multiple reaction vessels simultaneously is advantageous for large laboratories, as it only takes 30 minutes to complete a set of 36 vessels. With the ability to accommodate multiple pressurized vessels, or up to a 5 L open flask, the MARS 6 Synthesis offers both high throughput for larger labs and flexibility to run batch syntheses.

Why should I use a microwave?

Microwave technology has become a common tool for chemical synthesis both in academia and industry. Compared to conventional means of synthesis, the advantages of heating with a microwave include:

- Faster reaction times

- Greater yields

- Improved purity

- Better reproducibility

- Enhanced reaction control

Features

- 1800 watts delivered energy for rapid heating of reactions

(regardless of the number of vessels in the cavity) - Large microwave cavity allows for the greatest range of reaction vessels

- Specially designed cavity & waveguides to ensure uniform distribution of microwave energy (without the need for a mode stirrer)

- High resolution touchscreen with speakers

(No need for a laptop or external controller)

Safe & dependable cavity design.

The custom-engineered microwave cavity of the MARS 6 Synthesis is constructed of high-grade 316 solid-steel for maximum safety and coupled with a heavy-duty, spring-mounted door, featuring safety interlocks. CEM’s patented solid-state isolators protect the magnetron from reflected microwave energy, prolonging the lifespan of the system. Additional sensors ensure end-user safety at all times:

- Tempguard™ — user defined safe temperatures to prevent programming errors

- DuoTemp™ — optional dual-infrared and Fibre-optic temperature measurement that prevents exothermic reactions

- Reactiguard™ — acoustic sensor disables heating

- SafetyLock™ Door — reinforced, steel frame design

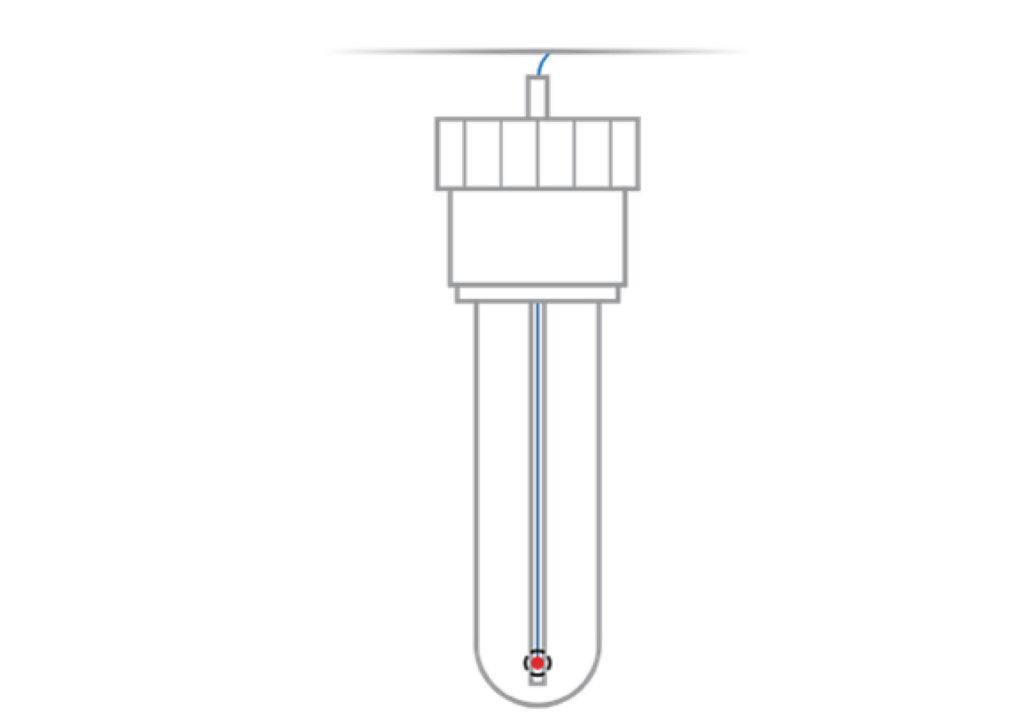

The most accurate temperature control available.

Fibre-optic Temperature Control provides the most precise temperature measurement available, by directly measuring the temperature inside the reaction vessel. Electromagnetic stirring helps to ensure maximum agitation for your reaction mixture. Adjust the speed to guarantee your sample mixes each and every time.

- In-situ, Fibre-optic temperature control comes standard on all MARS 6 Synthesis systems

- Optional, patented, floor mounted infrared temperature sensor

(not monitoring the side of the vessel) - Allows the most accurate temperature monitoring, independent of reaction volume

The most accurate temperature control available.

Fibre-optic Temperature Control provides the most precise temperature measurement available, by directly measuring the temperature inside the reaction vessel. Electromagnetic stirring helps to ensure maximum agitation for your reaction mixture. Adjust the speed to guarantee your sample mixes each and every time.

- In-situ, Fibre-optic temperature control comes standard on all MARS 6 Synthesis systems

- Optional, patented, floor mounted infrared temperature sensor

(not monitoring the side of the vessel) - Allows the most accurate temperature monitoring, independent of reaction volume

Multiple applications with one system.

Reduce cost of ownership, while maximizing productivity. With the MARS 6 Synthesis, it is possible to perform organic synthesis, inorganic chemistry, nanomaterials production, or even analytical sample preparation. The same microwave uses specialized vessel sets for a wide variety of applications.

Do you have any questions? Don´t hesitate to contact us.